Product Center

Spinneret Cleaning Equipment

Spinneret Cleaning Equipment

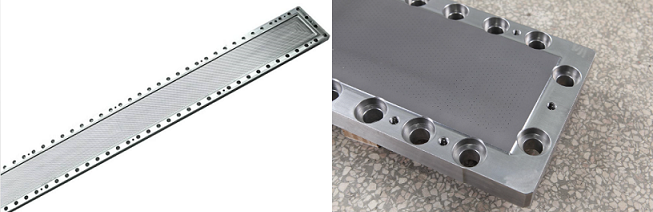

1.Cleaning object-spinneret plate

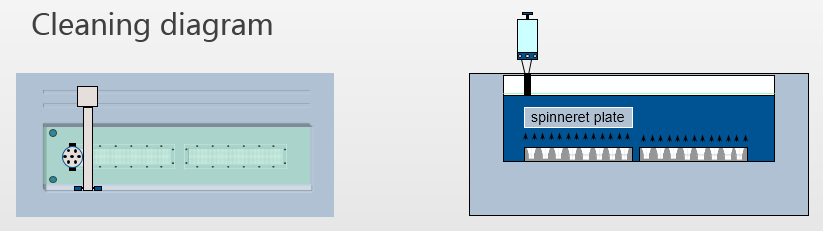

2. Cleaning process

Vacuum cleaning

Sonicleaning

Blow-dry

Microscopy

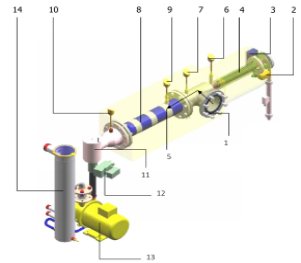

3. Main processes

A. Melt stage

The workpiece is heated up steadily in the vacuum state, melts most of the melt on the spinneret, and then falls into the waste collection tank.

B.Pyrolysis stage

Further heating will cause organic dirt to break down at high temperatures. Effective temperature control can avoid overheating of parts. The heating temperature can reach a maximum of 480℃. The whole process is conducted in a vacuum to avoid the heat dissipation reaction of organic gas.

C. Oxidation phase

The carbon crystallization of partial residual melt will be completely oxidized in the case of reduced vacuum.

D.cooling stage

After the cleaning process, open the furnace and remove the parts.

4. Device optional configuration

The device is installed at the inlet of the vacuum pipe and consists of a pipe, a stainless steel filter, a catalyst and an inlet valve. During vacuum extraction, viscous dust produced by vacuum pyrolysis in the furnace is burned at 600℃ to produce ash and gas, which overcomes the blockage of the pipeline and only emits carbon dioxide, water and a small amount of waste gas.

If the equipment is equipped with exhaust gas catalytic treatment device, the original equipment does not need to be equipped with "vacuum pipeline anti-blocking device".

5.Features of equipment

a. Combining shaped energy cleaning type with distributed cleaning, switching cleaning method up and down;

b. Micro holes and guide holes of spinneret are cleaned by shaped energy cleaning and distributed ultrasonic cleaning respectively, without turning plate;

c. Other instructions

Anti-splash design of control cabinet to prevent equipment damage from splash;

The electrical control is controlled by PLC, and the electronic control cabinet is centralized and independently controlled

Electrical heating

The transducer is equipped with anti-collision device to prevent damage caused by collision;

The generator has overcurrent, overload and short circuit protection functions;

The motor has phase loss, overload and stroke protection; The equipment has liquid level and anti-collision protection.