Product Center

Liquid Filter Bag/ Safety Filter & Filter Cartridge For Spunlace

Our company supplies various types of liquid bags, selecting a suitable bag is essential for the filter normal operation. In order to select the right filter, the key point to be considered are as follow, the cost,the filter pore size,the filter temperature resistance, as well as to analyze the chemical composition of the filtered impurities.

Characteristics:

1.HD high density liquid filter bags, able to filter large area,and instantly filter fluid impurities completely.

2.Bag material are with polyester, polypropylene and nylon.

3.Edge port of bag material: stainless steel ring, wire ring and plastic ring.

4.The HD bag and the filter can be completely consistent.

5.Using advanced technology to produce seamless welding, different from the traditional seam mode to improve the filtering accuracy.

6.Can be made to the special specifications of customer request.

PP.PE 1-200um grade liquid filter media:

The deep three-dimensional filter material, with 100% pure fiber of needle punched method to form a three-dimensional, high bulky, circuitous filter layers.

The loose fibrous tissue and high porosity increased impurities trapping on the fiber surface, while the fine particles are captured in the filter deep layers.This ensures the process does not damage the filter due to pressure increase, and thus achieves a higher filtration efficiency, by applying instant sintering technology / calendaring treatment, it can effectively prevent fibers loss by the high-speed liquid punching, it both ensures no losing fibers contamination, and avoid shortened lifetime caused by the traditional roll processing which blocks the bag pores, while without affecting the pressure difference and flow rate. We have filter fabrics of polypropylene, polyester and other materials, with filtering accuracy level 1-200um.

SAFETY FILTER & FILTER CARTRIDGE FOR SPUNLACE

| High pressure safety filter |

| Filter cartridge for spunlace |

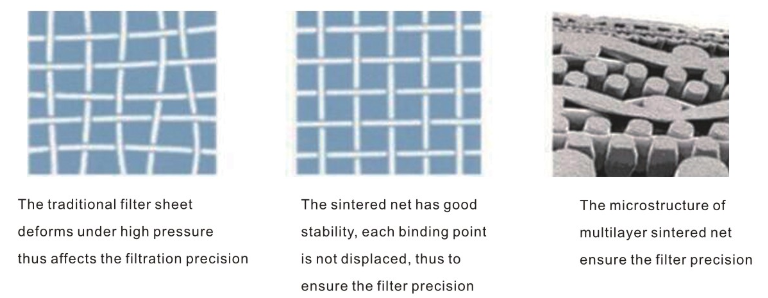

| Safety filter Our police filter has multi-layer net cartridges with sintering process,inside there is support frame. The filter uses folding technology to increase filtration area, the use of sintering technology is to ensure binding points under high pressure, no deformation to occur, this has increased the filter lifetime. It has provided high-quality products for many domestic spunlace producers. Sintering process applied, no distortion, achieves excellent filter effects. It is corrosion-resistant,easy to clean and easy for removal. |

| Filter cartridge |

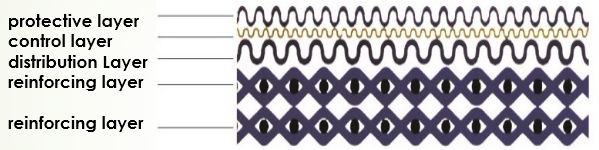

STRUCTURE

We supply various kind of sintered metal net, the multi-layer sintered mesh is of stainless steel net or sintered metal fiber felt (ranging from 2-50 layers). The 5-layer sintered net for example, is a normal type, it has 2 reinforcing layers, a distribution layer, a control layer, and a protective layer, stacking together and sintered at high temperature, then pressurized, is widely used in high temperature under high pressure and corrosion conditions, such as a polymer melt, sewage,chemicals and other filters.

In addition to the normal round and square sintered net, we can also process at customer demand or sample to design and process special sintered net, which max. size is up 650 mm x 1200 mm, with filtration precision at 0.5μm - 200μm.

The most typical and widely used filter cartridge type is from 5μm - 40μm precision sintered net in a cylindrical shape.